Gallery

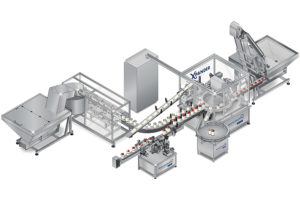

Xpander+ Automatic Packaging Machine Is The World’s First Complete Hands-Free Monoblock For Round Wipes In Canisters

The Xpander+ Automatic Packaging Machine differs from its sister unit (the Xpander) in that fully automatic feeders can be added to the existing modules. This in turn means that, so long as the lid and canister hoppers are kept filled (typically 2 or 3 times per shift), the Xpander+ can be operated completely ‘hands free’ and delivers much greater operating efficiencies.

With it’s unique all-in-one monoblock design, Xpander+ Automatic Packaging Machine encompasses all aspects of round wipes downstream packaging from cans & wipes feeding, loading, dosing, and sealing through to capping, a full built-in QC and smart weight checking. The Xpander has a throughput of up to 35ppm and is the only machine of its kind available on the market today.

The Xpander+ Automatic Packaging Machine is a robust, fully automatic, servo driven vertical index machine. It is specifically designed as a single block for the downstream packaging of round, nonwoven wet wipes in cans.

The Xpander Round Wipes Monoblock Packaging Machine has already been sold to multiple top tier wet wipes manufacturers

Benefits

- Height-adjustable filler nozzles. With every cycle the filling nozzle is set (prior to the actual portioning and filling) at a position inside the can exactly above the roll but below the can’s opening. This eliminates spillage and minimizes waste

- INDUSTRY 4.0 READY: SECOMA Site Manager 1139 modem, integrated into the machine HMI to enable SMART remote support, live stats and performance analysis as well as manufacturer enhancement feedback

- A newly developed capping mechanism for round cans lids Advanced QC including multiple check weighers and total QC for sealing and capping, significantly increasing efficiency

- Designed for operational flexibility and ultra low, tools free sub 40 minutes format parts changeover downtime

- All welded to pharma sanitary standards using 316/304 stainless steel.

- A newly developed design for vertical wipes can loading

- Easy-to-access ‘smart’ controls with multiple HMI’s around the Xpander for simple operation

- Throughput of 30-35 products/minute with up to 450cc liquid volume

- Up to five conveyors feeding into and out of the Xpander monoblock

- Direct and easy integration to the rewinding unit

- Adjustable rewinder-to-Xpander throughput technology

- Truly universal – supports both round, conic, rectangular & oval shaped cans, screw and push lids, and wrap around

- Front/back labelling